Bat Care

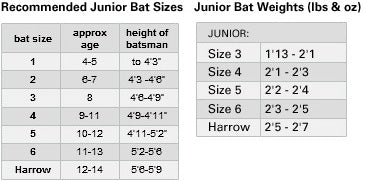

Blue Tongue Sports recommends following the following size guides when choosing your new bat.

JUNIOR BATS

SENIOR BATS

BAT CARE AND MAINTENANCE

IMPORTANT - Please read this before you use your bat

PREPARATION FOR PLAY

Blue Tongue Sports recommend the following principles for the preparation and maintenance of cricket bats. Following these procedures will significantly reduce the possibility of damage occurring. Oiling

All natural faced bats MUST be treated using raw linseed or a specialist cricket bat oil. The main purpose of oiling is to maintain moisture levels within the blade, and hence reduce the chances of cracking and splitting. Light coats should be applied to the face, edge, toe and back of the blade - taking care to avoid the logos and the splice area. Generally two or three coats should be sufficient. Each coat should be allowed to dry into the blade in a horizontal position before the next is applied.

WARNING

DO NOT STAND OVER OILDO NOT STAND THE BAT IN OILDO NOT STAND THE BAT IN A VERTICAL POSITION AFTER OILINGBATS WITH FULL PROTECTIVE COATINGS SHOULD NOT HAVE OIL APPLIED. BUT THEY MUST BE CONDITIONED AS DETAILED LATER

ALTERNATIVELY - It is possible to fit a clear Anti-scuff or similar cover. This does not negate the requirement to 'knock in' the bat. The cover may assist the durability of the bat, but under no circumstances will it totally prevent surface damage.

KNOCKING IN

All bats are pressed, however 'knocking in' is VITAL. This is the process by which the fibres of the willow in the face and edges are compressed together to form a barrier, which protects the bat against the impact of the ball.

Effective 'knocking in' will significantly improve the performance and increase the life span of the bat.

STAGE ONE

The 'knocking in' process should be undertaken carefully, using a special bat mallet or an old, quality cricket ball. The bat should be repeatedly struck (with gradually increasing force) in all areas where one would normally expect to hit the ball, this conditioning must be performed with patience. Particular attention should be given to the edges, although the edges or toe should not be struck directly at right-angles to the blade. This would be likely to cause damage. This stage should take in the region of six hours, although it may vary as every bat is different.

STAGE TWO

The next step is to graduate to the use of the bat to hit short catches with an old quality cricket ball. However, if the seam marks the blade, it is necessary to return to 'Stage one' for a further conditioning. This stage should be performed for at least another hour. Once these steps have been taken, the bat should be ready for use in matches. It is advisable to initially avoid use against the 'new ball'.

In addition to these steps, it is recommended that the purchaser follow closely the 'bat care' instructions issued by the manufacturer.

THE WORST THING A PLAYER CAN DO TO HIS BAT

Over Oil an untreated, plain, non-synthetically covered blade, thus increasing the weight and making the willow dead with no drive, this eventually gives the wood 'oil rot.Endeavor to wash it clean with water.Constantly lap the bit in the crease on a wet wicket, thus saturating the base of the bat, causing the pressing to lift and the base of the bat to swell and generally crack horizontally.Use it without Knocking in' or treatment.Continual 'edging' thus causing bruising and unnecessary indentations.Hit 'Yorkers' (blockholers on the toe of the blade, thus either denting and bruising the willow causing it generally to split horizontally but completely through the bat. This is more likely to happen on indoor, hard or synthetic wickets or at the beginning of the season when the ground is very hard.Using Cheap Cricket halls (especially those with hard centres) which bruise and dent the willow. Many bats are dented due to this reason.

ENJOY!

Cricket bats are made of willow. It is to be expected that the condition of the bat will deteriorate during its usage.

Irrespective of make or finish of a bat, superficial face and edge marks will almost certainly appear, together with indentations or bruising of the willow. This happens especially when 'poly type' coverings have been used, when the covering (a man-made fibre) does not react in exactly the same manner as willow (a natural fibre). In these circumstances there is no need to worry or concern as the durability and performance of the bat will be unaffected.

Almost all bats returned by worried customers, are not complaints due to manufacture but merely reactions of willow.